PADDY CLEANER DOUBLE DECKER

Apex Agrotec Pvt. Ltd. provides a fully automatic rice mill system that covers paddy cleaning, stone removal, milling, hulling, grain separation, and polishing. Our range of products includes various rice mill plants and machinery,

Specification- Paddy Cleaner Double Decker

Advantage- Paddy Cleaner Double Decker

1. Equipped with a highly efficient suction blower.

2. Designed to accommodate easily removable trays.

3. Provided with a conveyor system that easily

discharges immature paddy.

Paddy Cleaner Double Decker

Enquire Now

Efficiently transform harvested paddy into high-quality rice with our advanced processing equipment.

Subscribe to our YouTube channel now!

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

Efficient Cleaning & Destoning with Paddy Cleaner Double Decker

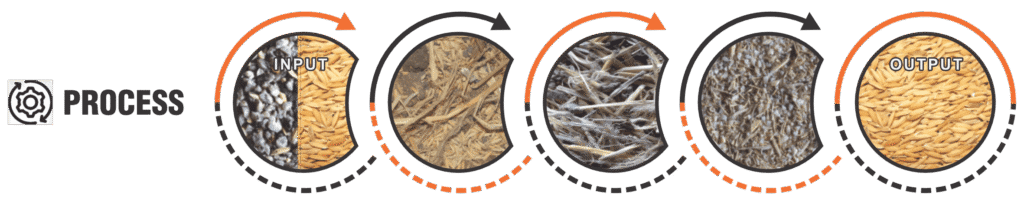

In rice milling and grain processing, maintaining the purity and quality of raw grains is essential. Before milling begins, the harvested crop contains several impurities such as straw, stones, mud balls, fine dust, and other unwanted particles. If these impurities are not removed in the initial stage, they affect the efficiency of the mill and lower the quality of the final product. To solve this problem, the paddy cleaner double decker is designed as a high-performance machine that ensures thorough cleaning while saving both time and operational costs.

Why Cleaning Is Essential Before Milling

Grains brought from the farm are often mixed with heavy and light impurities. Large straw pieces, mud lumps, and stones can damage machinery, while fine dust and sand reduce the overall rice quality. Pre-cleaning is, therefore, a mandatory step in every rice mill to protect machines and improve milling output. The paddy cleaner double decker plays a dual role by integrating both pre-cleaning and destoning into a single machine, ensuring efficient removal of contaminants.

Dual Function System for Maximum Efficiency

The biggest advantage of this machine is its ability to handle two operations at once. By combining pre-cleaning and destoning, the paddy cleaner double decker reduces the need for separate machines, saving space in the mill and cutting down on operational expenses. With its advanced air and gravity separation technology, the machine delivers excellent performance, ensuring high-quality grain output.

Key Features of Paddy Cleaner Double Decker

Dual Cleaning Function – Performs both pre-cleaning and destoning in one unit.

Two-Stage Cleaning System – Effectively separates light and heavy impurities.

Air & Gravity Separation – Removes dust, straw, and stones while protecting grain quality.

Durable Build – Strong design ensures long-term reliability in rice mills.

Energy Efficiency – Optimized to reduce power consumption without compromising results.

Specifications – Paddy Cleaner Double Decker 1500

The Paddy Cleaner Double Decker 1500 is a versatile machine that goes beyond paddy cleaning. It can be used for a variety of grains including dal (pulse), wheat, maize, soya bean, peas, and different seeds. Built with 7-layer sieves and a powerful blower, it ensures comprehensive cleaning for different crops.

-

Removes Oversized & Undersized Impurities – Eliminates straw, stones, twines, mud lumps, fine sand, and dust.

-

Multi-Grain Capability – Suitable for paddy, pulses, wheat, maize, and other seeds.

-

Advanced Blower System – Creates strong suction for removing fine impurities.

-

7-Layer Sieves – Guarantees precise separation and cleaning.

-

Built-in Conveyor System – Automatically discharges immature paddy.

Note: Specifications are subject to change due to continuous improvements and upgrades.

Advantages of Paddy Cleaner Double Decker

-

Highly Efficient Blower – Provides strong suction to remove dust and light particles effectively.

-

User-Friendly Design – Removable trays make it easy to clean and maintain.

-

Automatic Discharge System – The conveyor system ensures that immature paddy is separated and discharged smoothly.

-

Space Saving – Combines multiple functions in a single machine, reducing installation space.

-

Cost-Effective Operation – Cuts down on energy use and reduces the need for additional machines.

Applications of the Machine

The paddy cleaner double decker is widely used in:

-

Rice mills for pre-cleaning raw paddy.

-

Pulse and grain processing units for cleaning dal, maize, wheat, and peas.

-

Agro-industries where bulk grain cleaning is required.

-

Seed processing plants for ensuring impurity-free seeds.

Why Choose Apex Agrotec’s Paddy Cleaner Double Decker?

At Apex Agrotec Pvt. Ltd., we are committed to delivering reliable and efficient grain processing solutions. Our paddy cleaner double decker is designed with precision engineering to ensure high performance, durability, and ease of use. With advanced technology, long-lasting components, and energy-efficient systems, it provides rice millers and grain processors with the best possible solution for cleaning and destoning.

Conclusion

For rice mills and agro-processing industries, maintaining grain purity is crucial for delivering a premium final product. The paddy cleaner double decker is the perfect machine for this task, combining pre-cleaning and destoning in one system. With advanced features, robust construction, and proven efficiency, it ensures that grains are free from impurities while saving operational costs. Choosing Apex Agrotec’s innovative cleaning solution means better performance, higher grain quality, and long-term reliability.