VIBRO DESTONER / PADDY DESTONER

A vibro destoner is a highly efficient machine designed to remove stones, heavy impurities, and other foreign materials from grains, seeds, spices, and granular products. It works on the principle of gravity separation, utilizing vibrations to ensure that heavier particles settle at the bottom while lighter materials remain on the top.

Specification Vibro Destoner

A Vibro Destoner is a modern, highly efficient machine designed to remove stones, mud lumps, glass, and other heavy impurities from grains, seeds, pulses, and spices. It is widely used in rice mills, dal mills, flour mills, and seed processing plants to ensure high-quality, impurity-free output. In particular, the Paddy Destoner is an essential part of rice milling, where it ensures that paddy is completely stone-free before milling begins. By doing so, it not only improves rice quality but also prevents damage to expensive milling equipment. The Vibro Destoner and Paddy Destoner are advanced machines that combine vibration and gravity separation to deliver clean, safe, and stone-free grains. They improve product quality, protect downstream equipment, and increase overall productivity. For rice mills, dal mills, flour mills, and seed processors, these machines are a smart investment in efficiency, safety, and profitability.

Advantage Vibro Destoner

High Accuracy in Stone Removal – Effectively separates stones, glass, and other heavy impurities from grains.

Protects Machinery – Prevents damage to rice mills, grinders, and polishers, reducing downtime and repair costs

Vibro Destoner

Enquire Now

Efficiently transform harvested paddy into high-quality rice with our advanced processing equipment.

Subscribe to our YouTube channel now!

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

Vibro Destoner & Paddy Destoner – Advanced Grain Cleaning Machines

A Vibro Destoner is a modern, highly efficient machine designed to remove stones, mud lumps, glass, and other heavy impurities from grains, seeds, pulses, and spices. It is widely used in rice mills, dal mills, flour mills, and seed processing plants to ensure high-quality, impurity-free output. In particular, the Paddy Destoner is an essential part of rice milling, where it ensures that paddy is completely stone-free before milling begins. By doing so, it not only improves rice quality but also prevents damage to expensive milling equipment.

Working Principle

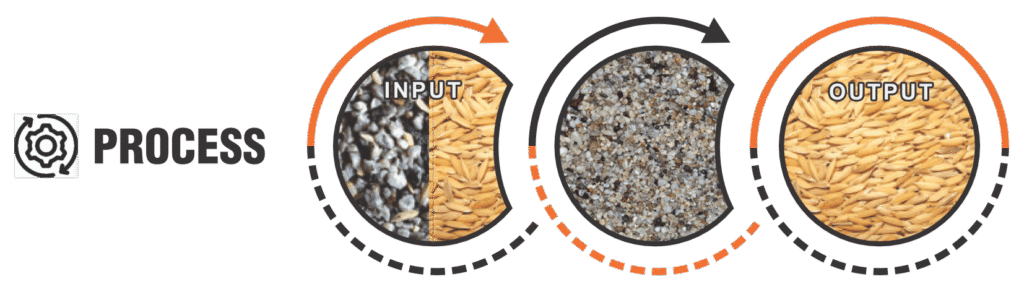

The Vibro Destoner operates on the principle of gravity separation combined with vibration technology. Grains and impurities are fed onto a vibrating deck. Because stones and heavy particles have greater density, they naturally move downwards, while lighter grains such as paddy, wheat, maize, and dal move upward. An airflow system further enhances separation, pushing lighter materials in one direction while heavier impurities move in the opposite direction.

In a Paddy Destoner, this system is particularly effective because harvested paddy often contains stones and mud balls. The machine ensures that only clean paddy passes forward for milling, leading to higher-quality rice and smooth milling operations.

Applications of Paddy Destoner

Both Vibro Destoner and Paddy Destoner are versatile and can be used for:

Rice Mills (Paddy Destoner): Remove stones and heavy impurities from paddy.

Wheat & Flour Mills: Ensures wheat is stone-free before grinding.

Pulse Processing Plants: Cleans dal and pulses effectively.

Maize & Corn Processing: Protects equipment by eliminating impurities.

Seeds & Spices: Provides pure, clean products ready for market.

Key Features

Accurate Stone Removal – CNC punched precision screens ensure perfect separation.

Compact Design – Occupies minimal floor space while offering maximum output.

Vibro Motor Technology – Uses vibration instead of moving mechanical parts, reducing wear.

Low Energy Consumption – Efficient operation with reduced power usage.

Easy Adjustments – Airflow, deck inclination, and vibration can be adjusted for different grains.

Hygienic Construction – Made with food-grade materials to maintain safety.

Benefits

Protects Machinery: Prevents damage to grinders, polishers, and milling equipment.

High Efficiency: Fast, accurate, and reliable impurity removal.

Low Maintenance: Vibro motors eliminate friction-based wear and reduce downtime.

Versatility: Can be used for rice, wheat, dal, maize, seeds, and spices.

Cost-Effective: Durable, long-lasting, and energy-efficient design.

Why Choose Apex Agrotec Paddy Destoner?

The Vibro Destoner and Paddy Destoner are critical machines for modern grain processors. A Paddy Destoner is a must for rice mills, where even small stones can reduce quality and harm machinery. By using a Paddy Destoner, millers ensure higher rice yield, improved quality, and longer equipment life.

The Vibro Destoner, on the other hand, is designed for multi-crop use. Whether it is wheat, maize, dal, seeds, or spices, the Vibro Destoner delivers consistent performance. Its compact design, robust build, and user-friendly operation make it suitable for both small units and large-scale processing plants.

Conclusion

The Vibro Destoner and Paddy Destoner are advanced machines that combine vibration and gravity separation to deliver clean, safe, and stone-free grains. They enhance product quality, safeguard downstream equipment, and boost overall productivity. For rice mills, dal mills, flour mills, and seed processors, these machines are a smart investment in efficiency, safety, and profitability.

By installing a Vibro Destoner or Paddy Destoner, processors can ensure that every batch of grains, pulses, or seeds is 100% clean, market-ready, and of the highest standard.