VIBRO SHELLER

A vibro sheller is an advanced machine designed for efficient dehusking and shelling of paddy and other grains. Using a combination of vibration and pneumatic pressure, this machine ensures gentle yet effective shelling, minimizing grain breakage while maximizing yield.

Specification- Vibro Sheller

The Vibro Sheller can shell up to 95% of various types of paddy, including raw, steamed, boiled, and basmati varieties. Vibro Sheller operates automatically to reduce operational costs. Additionally, it has a blower arrangement to prolong the life of the rubber rolls.

Advantage- Vibro Sheller

1. Installed with sleeve-type rubbers to get better

output and yield.

2. Equipped with specially designed exhaust cum

cooling blower to increase the life of the rubbers.

Vibro Sheller

Enquire Now

Efficiently transform harvested paddy into high-quality rice with our advanced processing equipment.

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

Vibro Pneumatic Rubber Sheller – High-Efficiency Shelling Machine

A Vibro Sheller, also known as a Rubber Sheller, is an advanced machine designed for the efficient dehusking and shelling of paddy and other grains. In modern rice mills and grain processing units, maintaining grain quality while ensuring maximum yield is critical. Traditional shelling machines often struggle to strike this balance, leading to higher grain breakage and lower profitability. The Vibro Sheller overcomes these challenges with its unique combination of vibration technology and pneumatic pressure, ensuring smooth, uniform, and high-quality shelling with minimal grain damage.

This machine is an indispensable part of modern rice milling, delivering not only efficiency but also precision. By applying controlled pressure through rubber rollers and enhancing the process with vibrations, the Vibro Sheller ensures the husk is removed gently, preserving the grain and maximizing recovery.

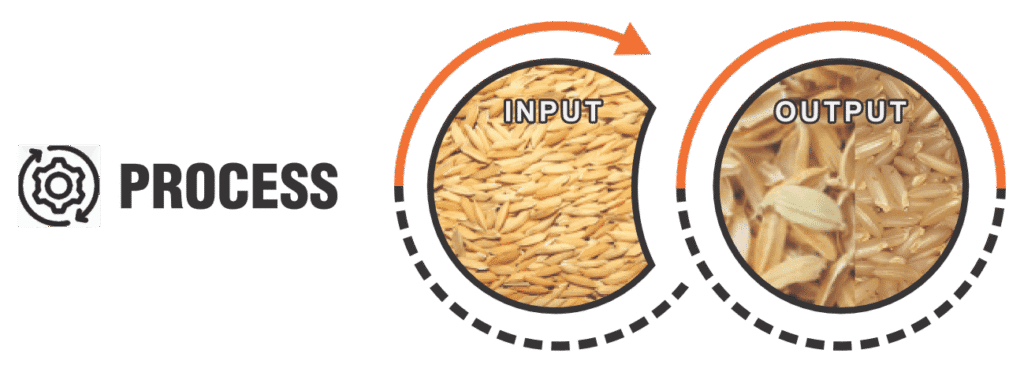

How the Vibro Sheller Works

The working principle of the Vibro Sheller revolves around its specialized rubber rollers and pneumatic system. Grains, typically paddy, pass through the rollers where controlled pressure is applied. Vibrations assist in loosening the husk, allowing it to separate efficiently. Unlike conventional shelling systems, where uneven pressure may cause breakage, the pneumatic adjustments in the Vibro Sheller allow operators to set precise parameters according to grain type and moisture content.

This process guarantees:

-

Uniform Dehusking: Every grain is shelled evenly, producing consistent results.

-

Minimal Grain Breakage: Gentle handling preserves kernels, improving yield.

-

High-Quality Output: The final product is clean, intact, and ready for further processing.

By combining vibration with rubber roller pressure, the Vibro Sheller ensures superior performance compared to traditional dehusking machines.

Key Features

The Vibro Sheller comes with a range of features that make it highly effective and reliable:

Vibration-Assisted Shelling – Smooth husk removal with minimal grain stress.

Pneumatic Pressure Control – Allows precise shelling adjustments for different paddy and grain types.

High Efficiency & Low Breakage – Maximizes yield while keeping grain intact.

Durable Rubber Rollers – Long-lasting, easy to maintain, and simple to replace.

Energy-Efficient Operation – Low power consumption with high output.

Compact & Robust Design – Built to withstand continuous industrial use.

Easy Operation – User-friendly controls for operators at all levels.

Applications

The Rubber Sheller is versatile and widely used across the grain processing industry:

Paddy Shelling: Ensures clean and efficient husk removal with minimal grain loss, essential for rice milling.

Grain Processing: Effective in dehusking wheat, maize, barley, and other cereals.

Seed Preparation: Produces high-quality, intact seeds ready for further processing or planting.

Whether in small units or large-scale rice mills, the Vibro Sheller guarantees consistent performance and higher returns.

Advantages

Choosing a Vibro Sheller offers several benefits:

Enhanced Productivity: High-capacity shelling ensures faster processing.

Better Grain Quality: Protects grains from breakage during shelling.

Lower Maintenance Costs: Durable rollers and robust design reduce downtime.

Cost-Effective Operation: Energy-efficient performance lowers running costs.

Long-Term Durability: Built with premium materials for continuous use.

Operator-Friendly: Simple controls and adjustments ensure ease of use.

Why Choose Apex Agrotec’s Pneumatic Vibro Sheller?

At Apex Agrotec Pvt. Ltd., we specialize in designing and manufacturing high-performance Vibro Shellers and Rubber Shellers that meet the growing demands of the agro-processing industry. Our machines are engineered with precision and cutting-edge technology, ensuring durability, efficiency, and consistent performance.

When you choose Apex Agrotec’s Vibro Sheller, you benefit from:

-

Superior grain quality with reduced breakage.

-

High-yield shelling and maximum recovery.

-

Easy-to-maintain rubber rollers with long service life.

-

Robust construction suitable for continuous industrial use.

-

Reliable after-sales service and technical support.

We understand that each grain counts in the processing business. Our Vibro Shellers are built to ensure that processors get maximum productivity with minimum grain loss.

Conclusion

The Vibro Sheller or Rubber Sheller is a revolutionary machine that combines vibration and pneumatic technology for high-quality shelling. It ensures uniform husk removal, protects grain integrity, reduces breakage, and maximizes yield. For rice mills, grain processors, and seed preparation units, this machine offers unmatched performance and efficiency.