PADDY SEPARATOR

A paddy separator is essential in rice milling, efficiently separating brown rice from paddy using weight, size, and shape differences. Whether you need a paddy separator machine or a paddy separator butterfly, understanding its function helps you choose the right one for your needs. The butterfly design ensures precise separation for better efficiency.

Specification- Paddy Separator

The Paddy Separator 2D Butterfly efficiently separates brown rice from paddy, Paddy Separator 2D handling higher capacities using gravity. Its double-sided tray oscillation motion takes up less space. Paddy Separator 2D operates with a sensor-controlled mechanism for consistent performance. 2D

Advantage

1. Complete automation capability with sensor.

2. Higher efficiency with low power consumption

3. Easy to operate and low maintenance costs.

Paddy Separator

Enquire Now

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

The Ultimate Guide to Paddy Separator

In modern rice mills, achieving high-quality output depends on how effectively paddy is separated from brown rice. The paddy separator plays a vital role in this process by ensuring that the mixture of paddy and brown rice is separated accurately. Without this step, the efficiency of the milling process is affected, and the quality of rice decreases. A well-designed paddy separator ensures that brown rice moves forward for polishing while the paddy is returned for dehusking, making the entire operation smooth and efficient.

How Does Work?

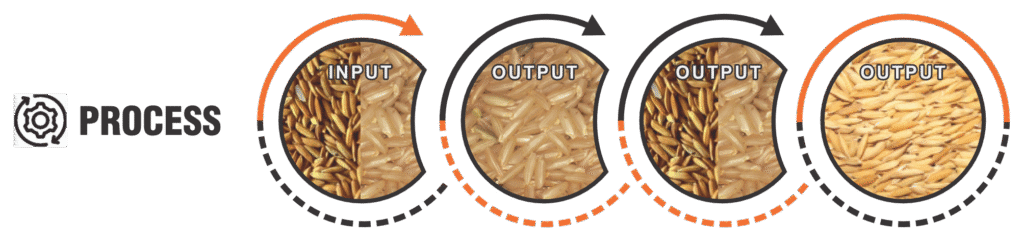

The working principle of a paddy separator is based on the difference in gravity and surface texture between paddy and brown rice. Here’s how the process happens:

Feeding Stage – A mixture of paddy and brown rice is fed into the machine.

Separation Stage – Using oscillating trays and gravity-based mechanisms, the machine sorts the lighter paddy grains from the heavier brown rice. Some machines also use vibrations or centrifugal force to increase accuracy.

Output Stage – The separated brown rice is collected in one compartment, while the paddy moves into another compartment for reprocessing.

This simple yet efficient process ensures maximum recovery of rice while reducing wastage.

Why Choose from Apex Agrotec Pvt. Ltd.?

At Apex Agrotec Pvt. Ltd., we focus on providing advanced rice milling machines that meet the modern needs of rice processors. Our paddy separators are designed to ensure consistent performance, durability, and energy efficiency. Built with precision, these machines improve overall rice milling efficiency and guarantee better grain quality.

Key Benefits of Our Paddy Separator

Advanced Technology – Incorporates the latest gravity and oscillation mechanisms for precise separation.

Durable Design – Made from high-quality materials for long-lasting use.

Energy Efficient – Low power consumption ensures cost-effective operation.

Compact & Space-Saving – Specially engineered to fit easily in modern rice mills.

Custom Solutions – Available in different models to suit small, medium, and large-scale rice mills.

Specification – Paddy Separator 2D Butterfly

One of the most popular models offered by Apex Agrotec is the Paddy Separator 2D Butterfly. This machine is designed for higher capacity handling and ensures precise separation of paddy from brown rice.

Efficient Separation – Uses double-sided tray oscillation motion for accuracy.

Space-Saving Design – Compact machine that requires less installation space.

Sensor-Controlled Operation – Equipped with a sensor mechanism to maintain consistent performance.

Gravity-Based Functionality – Utilizes the natural difference between paddy and brown rice for separation.

Note: Specifications may change due to continuous improvements and upgrades.

Advantages of Paddy Separator 2D

Complete Automation – Sensor-controlled system enables fully automatic operation.

High Efficiency – Achieves maximum separation with minimum grain loss.

Low Power Consumption – Designed for energy savings, reducing overall operational costs.

Easy to Operate – User-friendly design suitable for operators at all skill levels.

Low Maintenance – Built with strong components that require minimal servicing.

Applications

The paddy separator is widely used in:

Rice Mills – To separate brown rice from paddy for further polishing.

Agro-Processing Units – For improving the overall efficiency of grain handling.

Large-Scale Milling Plants – To handle high-capacity separation requirements.

Export Quality Rice Production – Ensures premium rice quality by reducing impurities.

Why Apex Agrotec is the Right Choice

Choosing the right paddy separator is crucial for the success of rice milling operations. Apex Agrotec Pvt. Ltd. offers machines that are not only efficient but also durable, reliable, and cost-effective. With our continuous innovation and customer-first approach, we have become a trusted partner for rice mills across India and international markets.

Conclusion

The paddy separator is a key machine in rice milling, ensuring proper separation of brown rice from paddy. Apex Agrotec’s Paddy Separator 2D Butterfly model combines modern technology, durability, and energy efficiency to deliver the best results. By investing in this advanced machine, rice millers can increase productivity, improve rice quality, and reduce operational costs. For reliable rice milling solutions, Apex Agrotec provides the expertise and technology you can trust.