BRAN CENTRIFUGAL

Apex Agrotec Pvt. Ltd. provides a fully automatic rice mill system that covers paddy cleaning, stone removal, milling, hulling, grain separation, and polishing. Our range of products includes various rice mill plants and machinery,

Specification- Bran Centrifugal

The Bran Centrifugal machine is strongly made of heavy metal angles, metal sheets, and a sturdy shaft. Bran Centrifugal has really good bearings and housings to keep dust out. Apex Agrotec Bran Centrifugal has a very wide application. It is used for the separation of left-out rice tips from brawn-in rice.

Advantage- Bran Centrifugal

1. Low energy consumption.

2. The nylon net in the machine helps high-quality powder

get filtered and collected in a bag.

3. It also has a nylon brush to clean the net.

Bran Centrifugal

Enquire Now

Efficiently transform harvested paddy into high-quality rice with our advanced processing equipment.

Subscribe to our YouTube channel now!

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

Bran Centrifugal – High-Efficiency Bran Filter for Rice Mills

The Bran Centrifugal is a specialized machine designed to separate leftover rice tips from bran during the rice milling process. It is an essential component for modern rice mills that focus on achieving high-quality output with minimal wastage. Built with a robust structure using heavy metal angles, durable sheets, and a strong shaft, the Bran Centrifugal is engineered for long-lasting performance and reliable operation even under continuous use.

One of the key highlights of the Bran Centrifugal is its advanced Bran Filter mechanism. Equipped with high-quality bearings and sealed housings, the machine effectively prevents dust leakage, ensuring a clean working environment and superior filtration results. This makes it highly efficient in separating fine rice particles from bran, delivering improved rice quality and value-added by-products.

How the Bran Centrifugal Works

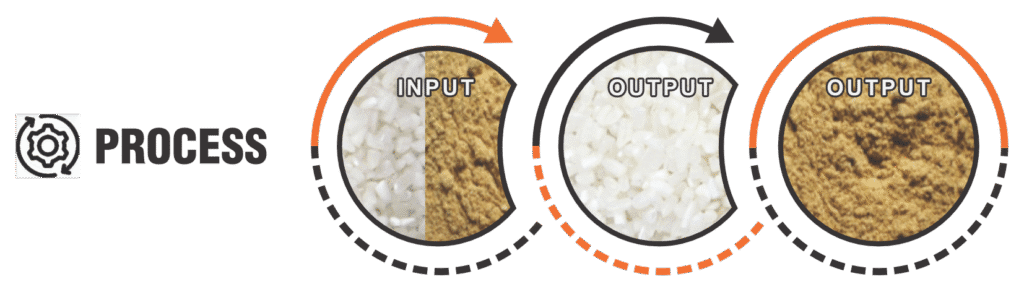

The Bran Centrifugal operates on the principle of centrifugal force combined with a nylon bran filter system. When bran mixed with fine rice tips is fed into the machine, the rotating shaft and mesh filter separate the finer rice particles from the coarser bran.

The nylon net filter allows only fine particles to pass through, ensuring high-quality powder collection.

A nylon cleaning brush continuously cleans the filter, preventing clogging and maintaining efficiency.

The collected fine powder is then stored in a bag, while the bran is separated for further processing or disposal.

This process guarantees maximum recovery of rice tips while ensuring bran remains clean and usable for other purposes such as cattle feed or by-products.

Key Features Strong & Durable Construction –

Made with heavy metal angles, sheets, and a sturdy shaft for long-lasting performance.

Efficient Bran Filter System – Nylon net ensures precise separation of fine particles from bran.

Dust-Proof Design – Bearings and housings are specially designed to prevent dust leakage.

Self-Cleaning Mechanism – Nylon brush automatically cleans the net, ensuring continuous operation.

Low Energy Consumption – Optimized design minimizes power usage while maintaining high output. Compact & Reliable – Space-saving design suitable for small and large rice mills alike.

Advantages

Low Energy Consumption – Operates efficiently with reduced power requirements, lowering operational costs.

High-Quality Filtration – The nylon net acts as an advanced bran filter, ensuring only fine rice powder passes through while separating coarser particles.

Continuous Cleaning System – Nylon brush keeps the filter net clean, avoiding blockages and maintaining smooth operation.

Improved Rice Recovery – Helps recover leftover rice tips from bran, increasing yield and reducing wastage.

Dust-Free Operation – Sealed bearings and housings keep dust contained, maintaining a cleaner milling environment.

Versatile Applications – Suitable for different varieties of paddy and bran separation in rice mills.

Applications of Bran Filter

The Bran Centrifugal with its integrated Bran Filter is widely used in rice mills for:

Separation of fine rice tips from bran-in rice.

Collection of high-quality rice powder for further processing.

Producing cleaner bran suitable for cattle feed and by-products.

Enhancing overall efficiency and profitability of rice milling operations.

Why Choose Apex Agrotec’s Bran Centrifugal?

At Apex Agrotec Pvt. Ltd., we design and manufacture high-performance Bran Centrifugals and Bran Filters that meet the needs of modern rice mills. Our machines are built with cutting-edge technology, robust materials, and user-friendly features, ensuring durability, efficiency, and ease of maintenance.

When you choose Apex Agrotec’s Bran Centrifugal, you benefit from:

Superior bran separation and rice recovery.

Heavy-duty construction for long-lasting performance.

Low maintenance requirements due to self-cleaning design.

Reliable after-sales service and technical support.

Conclusion

The Bran Centrifugal is a vital machine for rice mills, designed to maximize rice recovery while maintaining the purity of bran. Its efficient bran filter system ensures that fine rice particles are collected and separated from bran with minimal energy consumption.

By investing in Apex Agrotec’s Bran Centrifugal, rice processors can achieve higher productivity, better product quality, and reduced wastage. Compact, efficient, and durable, it is the perfect solution for any rice mill seeking to optimize its milling process.