HUSK ASPIRATOT

Apex Agrotec Pvt. Ltd. provides a fully automatic rice mill system that covers paddy cleaning, stone removal, milling, hulling, grain separation, and polishing. Our range of products includes various rice mill plants and machinery,

Specification

The Husk Aspirator DLX is a machine that separates the shelled husk from brown rice. It comes with an inbuilt hopper arrangement to avoid losing valuable grains. The For Husk Aspirator parts that are likely to wear out due to the abrasive nature of the husk aspirator are made with stainless steel in the necessary areas.

Advantage

1. Equipped with a powerful blower for husk

separation.

2. Immature paddy separated via a conveyor.

Husk Aspirator

Enquire Now

Efficiently transform harvested paddy into high-quality rice with our advanced processing equipment.

Subscribe to our YouTube channel now!

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

Husk Aspirator – Advanced Grain Cleaning Solution

In modern rice mills and grain processing plants, efficiency and quality are the two most important factors. Every step in the milling process must be carried out with care to ensure that the final product is clean, safe, and market-ready. One important step in this chain is the separation of husk from brown rice. For this purpose, industries rely on a machine known as the husk aspirator, which is specially designed to separate the husk layer after shelling. By removing light particles and impurities at the right stage, this equipment helps maintain both product quality and plant efficiency.

Strong Construction and Design

The machine is built to handle the abrasive nature of rice husk without losing performance over time. Parts that are most likely to wear out are made of stainless steel, which ensures durability and long life. The design includes a well-structured hopper arrangement, so valuable grains are not lost during the process. This thoughtful construction makes the unit reliable for continuous use in rice mills of all sizes.

How the Machine Works

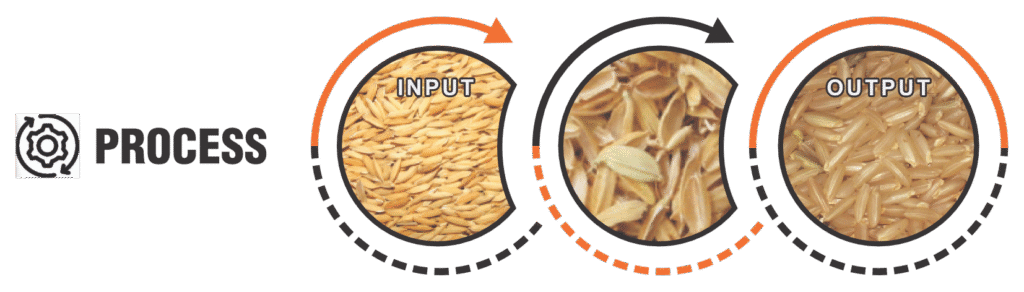

The working principle is simple but highly effective. When the paddy is shelled, a mixture of brown rice and husk is produced. This mixture enters the aspirator chamber, where a strong blower creates an airflow. The lighter husk particles are lifted and carried away through the air channel, while the heavier brown rice falls back into the collection outlet. This separation is efficient and minimizes grain loss, resulting in higher recovery of edible rice.

Another important function of the machine is the removal of immature or unfilled paddy grains. These lighter grains are carried along with the husk and directed away using a conveyor, ensuring that only mature rice continues to the next stage of processing.

Key Features

Durable Stainless-Steel Parts – Areas prone to abrasion are reinforced for long service life.

Inbuilt Hopper System – Prevents unnecessary grain loss during operation.

Powerful Blower – Ensures complete husk removal without affecting grain quality.

Conveyor for Immature Paddy – Separates unfilled grains and keeps final output clean.

Easy Maintenance – Designed for simple cleaning and upkeep to minimize downtime.

Advantages

Efficient Husk Separation – A powerful blower makes sure the husk is removed quickly and cleanly.

Better Grain Recovery – The inbuilt hopper ensures that valuable rice grains are not lost with the husk.

Durable and Reliable – Stainless-steel construction in critical areas extends machine life.

Improved Product Quality – By removing husk and immature paddy, the rice output is cleaner and ready for further processing.

Low Maintenance Requirement – Simple design reduces wear and tear, saving time and cost for mill owners.

Applications in Agro-Processing

The machine is widely used in rice mills, seed processing units, and agro-industries where separation of husk is essential. It plays a vital role in improving milling efficiency and ensuring a higher yield of quality rice. By handling both husk removal and separation of immature grains, it reduces manual labor and increases the overall speed of operations.

Why Choose Apex Agrotec?

At Apex Agrotec Pvt. Ltd., we focus on designing machines that combine performance with durability. Our husk aspirator is built using high-grade materials and modern technology, ensuring reliable operation even under continuous use. We provide machines that are easy to maintain, energy-efficient, and capable of meeting the demands of both small and large processing plants.

Conclusion

A well-designed husk separation system is essential for maintaining quality in rice milling. The husk aspirator not only removes the husk effectively but also prevents immature grains from entering the final product. With its strong construction, simple operation, and efficient design, this machine is a valuable addition to any rice mill. By choosing Apex Agrotec’s solution, millers can achieve better productivity, higher grain recovery, and superior product quality, all while reducing operational costs.