PADDY CLEANER

Apex Agrotec Pvt. Ltd. provides a fully automatic rice mill system that covers paddy cleaning, stone removal, milling, hulling, grain separation, and polishing. Our range of products includes various rice mill plants and machinery, with a special focus on paddy cleaner and pre-cleaning equipment, ensuring effective impurity removal and high-quality rice production

Specification- Paddy Cleaner

The Paddy Cleaner Mega series is designed to clean paddy, dal (pulse), wheat, maize, soya beans, peas, and all types of seeds and pulses. Paddy Cleaner removes big and small impurities like stones, straws, mud lumps, twines, fine sand, and dust. With its 4-layer sieves and built-in blower, it makes sure that the paddy is cleaned efficiently.

Advantage- Paddy Cleaner

1. Equipped with a highly efficient suction blower.

2. Designed to accommodate easily removable trays.

3. Provided with a conveyor system that easily discharges

immature paddy.

Paddy Cleaner

Enquire Now

Efficiently transform harvested paddy into high-quality rice with our advanced processing equipment.

Subscribe to our YouTube channel now!

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

Paddy Cleaner – Efficient Cleaning & Destoning Solution

A Paddy Cleaner is an essential machine in modern rice mills, designed to ensure clean, impurity-free paddy before it enters the milling process. When raw paddy is brought from the farms, it often contains a variety of impurities such as dust, straw, stones, sand, mud balls, and other unwanted particles. If these impurities are not removed in the initial stage, they can affect grain quality, damage milling equipment, and reduce the final yield. This is why a Paddy Cleaner is considered the first and most crucial step in rice processing.

By combining pre-cleaning and destoning functions, the Paddy Cleaner not only improves the overall quality of paddy but also saves time, space, and operating costs for millers. It ensures that the raw material is thoroughly cleaned and prepared for storage or further processing.

Dual Function System – Cleaning & Destoning in One Machine

One of the biggest advantages of a modern Paddy Cleaner is its dual-function system. Instead of using two separate machines for cleaning and destoning, this integrated system performs both tasks efficiently in a single unit.

Pre-Cleaning: Removes large impurities such as straw, husk, dust, sand, and mud balls.

Destoning: Separates heavier impurities like stones and metallic particles that may be mixed with paddy during harvesting and transportation.

This combined system ensures excellent performance, reduces machine footprint, and lowers operational costs without compromising output quality.

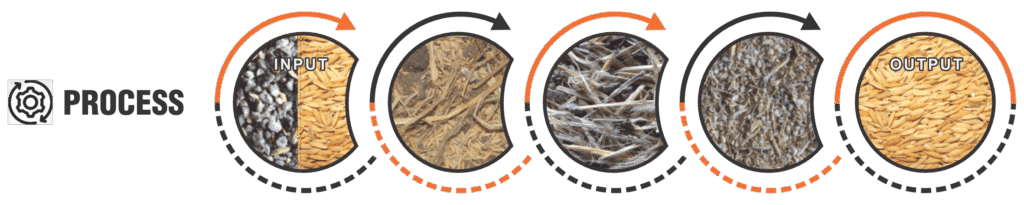

How the Paddy Cleaner Works

The Paddy Cleaner operates on the principles of air separation, gravity separation, and sieving technology. The raw paddy is fed into the machine, where it undergoes a two-stage cleaning process:

Stage One – Pre-Cleaning:

Using sieves and airflow, large and light impurities such as dust, straw, and husk are removed. This ensures that the bulk paddy is free from visible impurities.Stage Two – Destoning:

The cleaned paddy is then passed over a vibrating deck with controlled airflow. Due to the difference in density, heavier materials like stones and metallic particles settle and are separated from the lighter paddy grains.

This two-stage process guarantees maximum impurity removal and prepares paddy for smooth milling operations.

Key Features of Paddy Cleaner

Dual Cleaning Function – Combines pre-cleaning and destoning in one machine for complete impurity removal.

Two-Stage Cleaning System – Ensures superior separation of both light and heavy contaminants.

Advanced Air & Gravity Separation – Protects grain quality while efficiently removing dust, straw, and stones.

Robust & Durable Design – Built with heavy-duty materials for reliable, long-term performance in rice mills.

Energy-Efficient Operation – Optimized system reduces power consumption while maintaining high output.

Compact & Space-Saving – Integrates two processes in one machine, reducing the overall footprint in the mill.

Benefits of Using a Paddy Cleaner

Improved Grain Quality: Only clean, impurity-free paddy enters the milling stage.

Protects Milling Equipment: Prevents stones and mud balls from damaging polishers and grinders.

Higher Efficiency: Faster and more accurate impurity removal boosts productivity.

Cost-Effective: Reduces the need for multiple machines, lowering installation and maintenance costs.

Long Service Life: Built to withstand continuous use in industrial rice mills.

Versatile Use: Suitable for all types of raw paddy from farms.

Why Choose Apex Agrotec’s Paddy Cleaner?

At Apex Agrotec Pvt. Ltd., we manufacture high-performance Paddy Cleaners that meet the growing demands of the rice processing industry. Our machines are engineered with precision technology to deliver maximum cleaning efficiency, low power consumption, and long-lasting durability.

By choosing our Paddy Cleaner, you benefit from:

Superior cleaning and destoning accuracy.

Reliable and heavy-duty construction.

User-friendly operation and easy maintenance.

Technical support and after-sales service.

With Apex Agrotec’s Paddy Cleaner, rice millers can achieve consistent quality, reduced wastage, and higher profits.

Conclusion

A Paddy Cleaner is the backbone of the rice milling process, ensuring that raw paddy is free from impurities before milling. By combining pre-cleaning and destoning in a single system, it saves time, reduces costs, and improves efficiency. Whether for small-scale rice mills or large industrial units, a Paddy Cleaner is the most effective solution for achieving clean, high-quality paddy ready for processing.