SHIFTER

Apex Agrotec Pvt. Ltd. provides a fully automatic rice mill system that covers paddy cleaning, stone removal, milling, hulling, grain separation, and polishing. Our range of products includes various rice mill plants and machinery,

Specification- Shifter

The Shifter sorts grains of different sizes based on their length and separates tips, small broken pieces, broken grains, and head rice. It has a self-cleaning feature to keep its performance consistent. Shifter aspiration system stops dust and bran from getting out of the machine, making sure it runs cleanly and improves plant hygiene.

Advantage- Shifter

1. Designed with an easily removable trey system

2. Equipped with a special spray gun to give uniformly silk rice.

3. Suitable for raw, steamed, ed, and boiled rice and gives a high

degree of finish to the rice.

Rotary-Shifter

Enquire Now

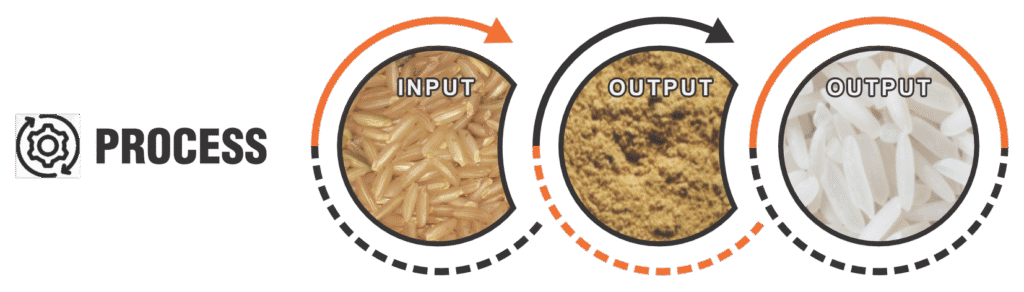

Efficiently transform harvested paddy into high-quality rice with our advanced processing equipment.

Subscribe to our YouTube channel now!

Got any questions?

Our experts will be happy to connect with you & guide you to choose right products.

Shifter Machine – Efficient Grain Sorting for Rice Mills

In rice milling and grain processing, precision sorting is essential for delivering high-quality output. A shifter plays a critical role in this process by separating grains according to their size and length. This ensures that head rice, broken grains, small pieces, and tips are sorted efficiently, resulting in a cleaner and more refined final product.

At Apex Agrotec Pvt. Ltd., we design high-performance shifter machines that combine accuracy, durability, and efficiency. With a built-in self-cleaning system and advanced aspiration technology, our machines guarantee smooth operation while maintaining excellent plant hygiene.

How Does Work?

The working principle of a shifter is straightforward yet highly effective. Grains of varying lengths and sizes are fed into the machine, where they pass through specially designed trays and sieves. These components separate the grains into categories such as:

Head Rice – Long and uniform grains.

Broken Grains – Medium-sized pieces.

Small Broken Pieces – Tiny fragments of rice.

Tips – Short ends of grains.

The built-in aspiration system prevents dust and bran from escaping, improving overall hygiene in the milling plant. Additionally, the self-cleaning mechanism ensures the shifter maintains consistent performance without frequent manual cleaning.

Key Features

These features make the shifter an essential part of any modern rice mill.

Specification

Separates head rice, broken grains, tips, and small pieces effectively.

Equipped with an easily removable tray system for simple maintenance.

Built-in self-cleaning mechanism for consistent performance.

Advanced aspiration technology to stop dust and bran leakage.

Suitable for raw, steamed, boiled, and parboiled rice varieties.

This flexibility makes the shifter a versatile machine that supports a wide range of rice processing requirements.

Advantages

Easy Maintenance – Designed with removable trays for quick cleaning.

Uniform Rice Quality – Equipped with a spray gun to achieve uniformly silky rice.

Versatility – Suitable for all types of rice including raw, steamed, boiled, and parboiled.

High Degree of Finish – Improves the final appearance and quality of rice.

Plant Hygiene – Dust and bran control ensures a cleaner working environment.

By integrating a rotary shifter, rice mills can further improve efficiency and ensure continuous separation with minimal downtime.

Rotary Shifter – Advanced Grain Sorting

While traditional models provide reliable sorting, the rotary shifter offers an even higher level of precision and speed. Its rotary motion improves the separation process, making it ideal for large-scale rice mills with higher production demands.

Benefits of a Rotary Shifter:

Handles higher capacities with consistent output.

Provides smoother operation with less vibration.

Ensures enhanced grain separation and minimal wastage.

Long-lasting performance even in continuous operations.

For rice processors looking for efficiency and durability, the rotary shifter is the perfect choice.

Why Choose Apex Agrotec?

Our shifters, including rotary shifter models, are widely used across India and internationally. They are trusted by rice millers for improving plant efficiency while delivering superior quality rice.

Conclusion

A shifter is one of the most important machines in rice milling, ensuring grains are separated accurately into head rice, broken pieces, tips, and small fragments. With features like self-cleaning, aspiration control, and easy tray removal, it guarantees smooth operation and consistent results.

For higher efficiency and large-scale operations, the rotary shifter provides an advanced solution, combining speed, durability, and precision.

At Apex Agrotec Pvt. Ltd., we specialize in manufacturing world-class shifters designed to meet the evolving needs of rice mills. Choose Apex Agrotec’s Shifter Machine to enhance your milling process with accuracy, efficiency, and reliability.